MES

Frontend experience with React.js and Next.js. Skilled in backend development using Node.js and Express.js focusing on developing scalable and secure APIs. Comfortable working with various databases like MongoDB, Mysql and MariaDB. Possesses practical knowledge of containerization and orchestration tools like Docker and Kubernetes for streamlined deployments. Understands and can implement CI/CD practices using GitLab CI for efficient development workflows. Actively learning and expanding skill set.

ARA Consulting

FullStack Developer - -

Play a dynamic role within a cross-functional development team, contributing to the creation of Manufacturing Execution System (MES) solutions for various clients, using a multi-service architecture.

MES

Andon Post

PDA

Website

Website

Website

Higher Institute of Technological Studies of Radès

Bachelor's degree in Mechatronics - -

High School of El Mourouj 6

Technological baccalaureate - -

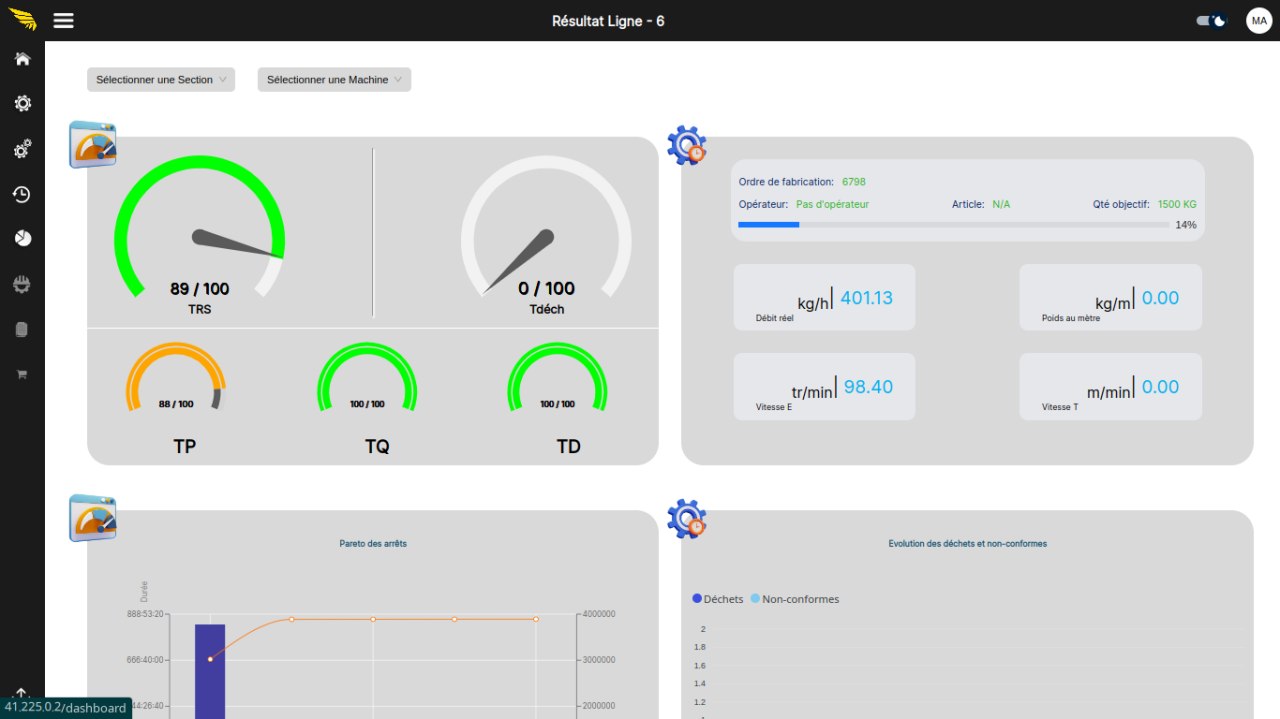

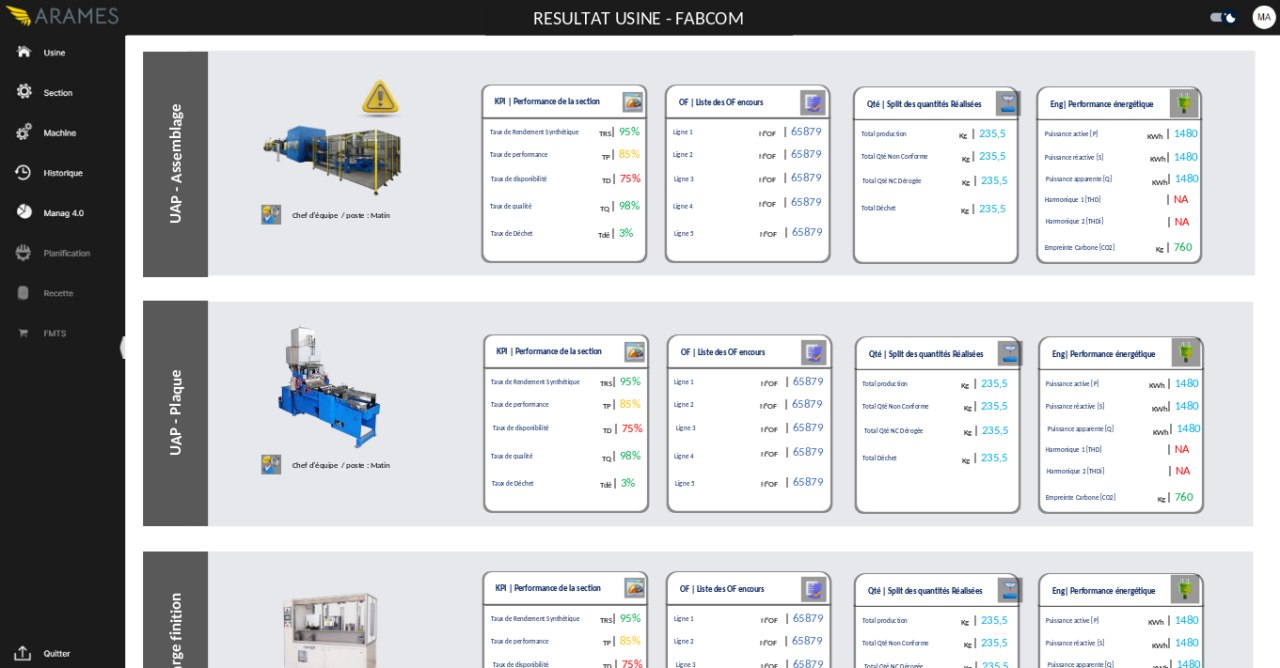

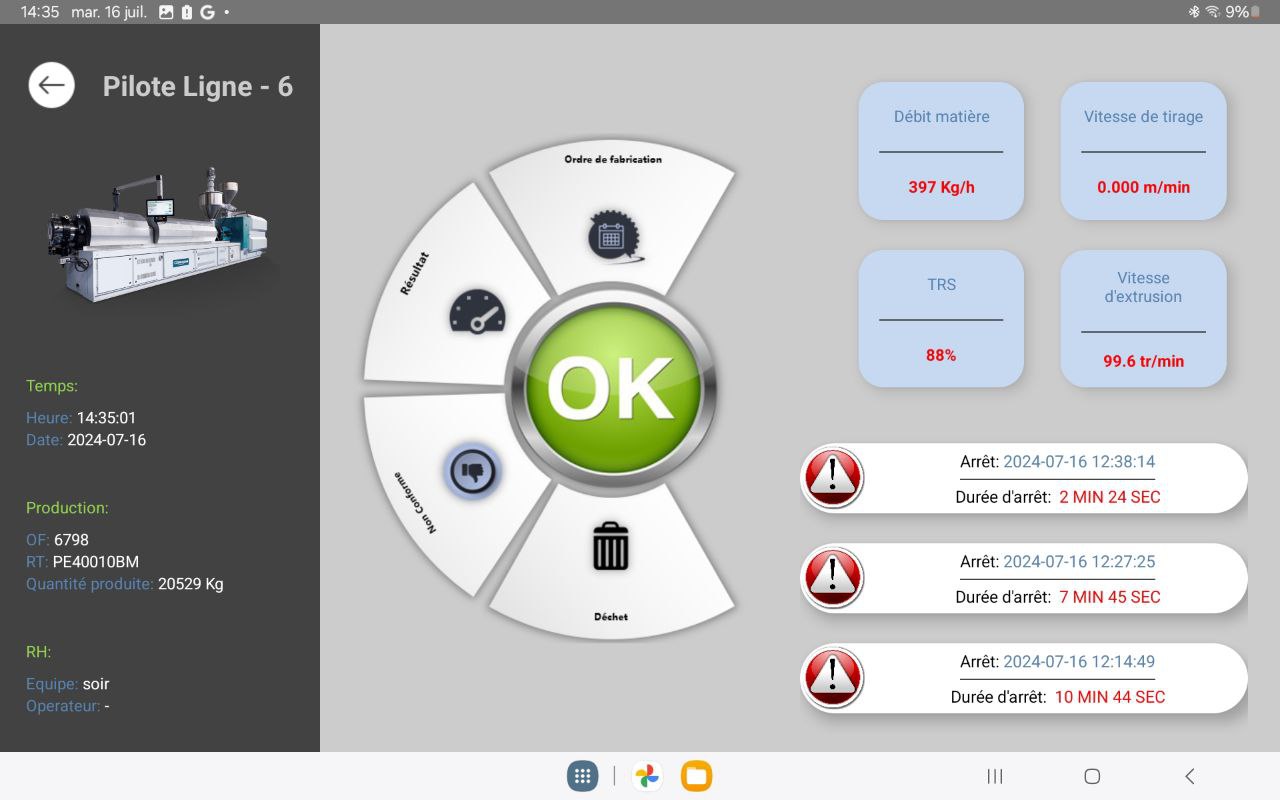

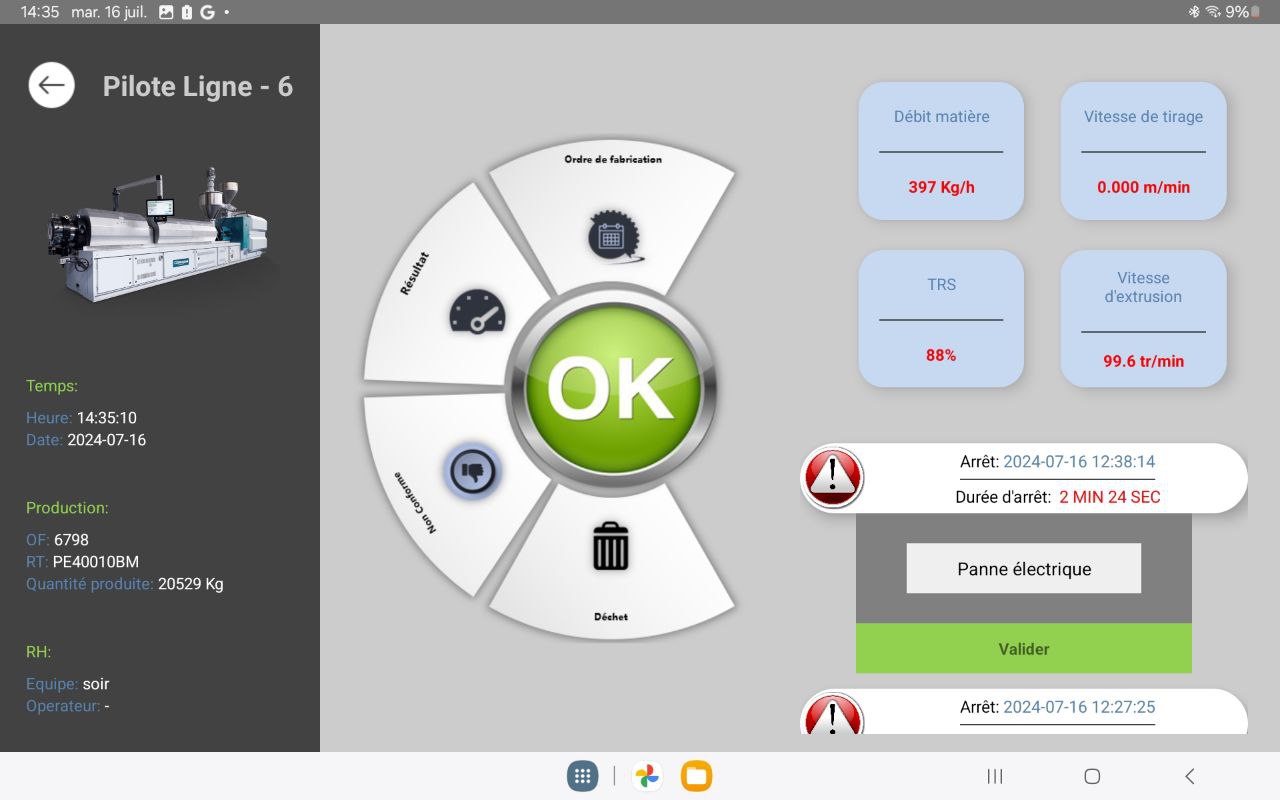

Manufacturing Execution System

Our advanced Manufacturing Execution System

(MES) is designed to enhance productivity and

optimize the manufacturing process through

real-time data integration. It continuously

monitors machine performance, work, and stop

times, automatically calculating and tracking

Key Performance Indicators (KPIs), throughput,

and downtime. The system maintains a detailed

history of production activities, ensuring

traceability and compliance, while providing

predictive maintenance insights through machine

performance analysis. The MES features three

user interfaces: an admin interface for system

configuration and detailed reporting, an

operator interface for real-time monitoring and

task management, and an Andon post interface for

visual communication of production status and

issues. This comprehensive MES solution ensures

efficient and transparent manufacturing

operations, empowering data-driven

decision-making and fostering rapid response to

production challenges.

Live Demo

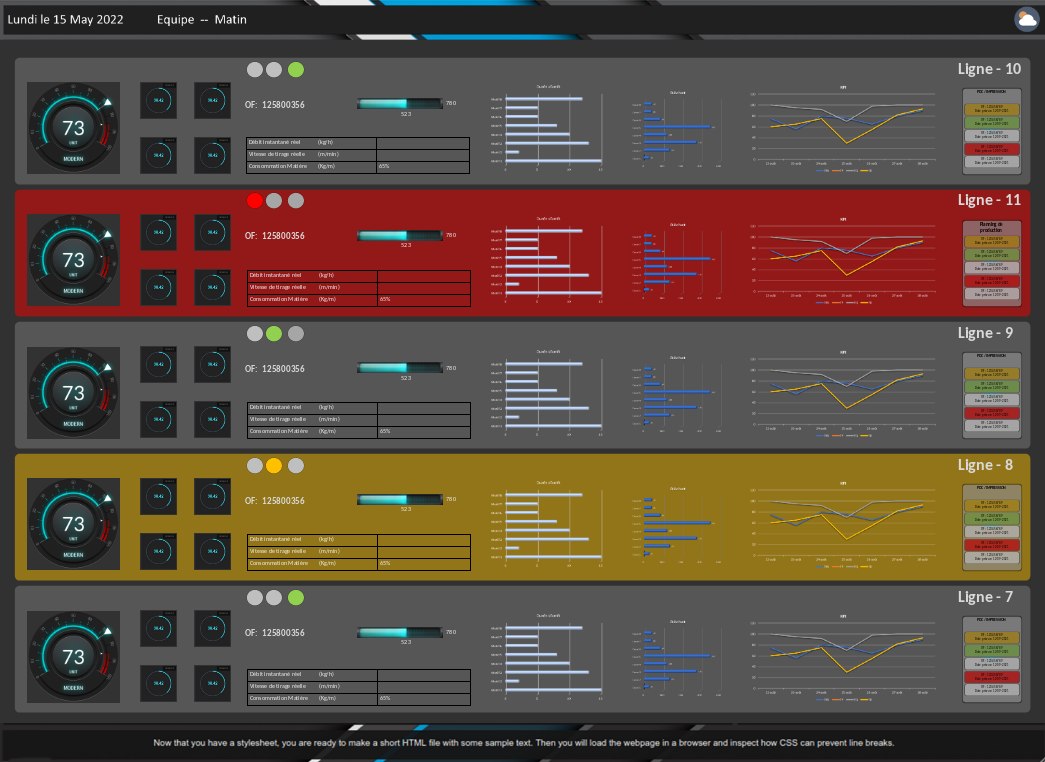

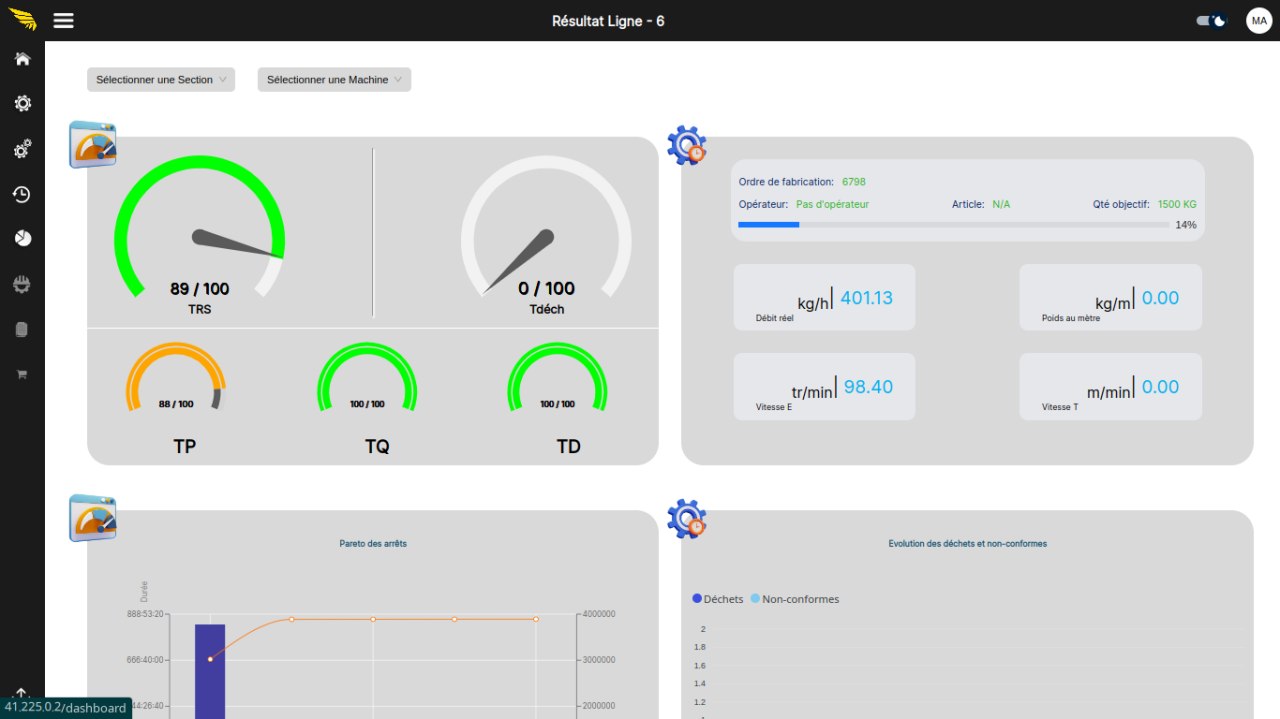

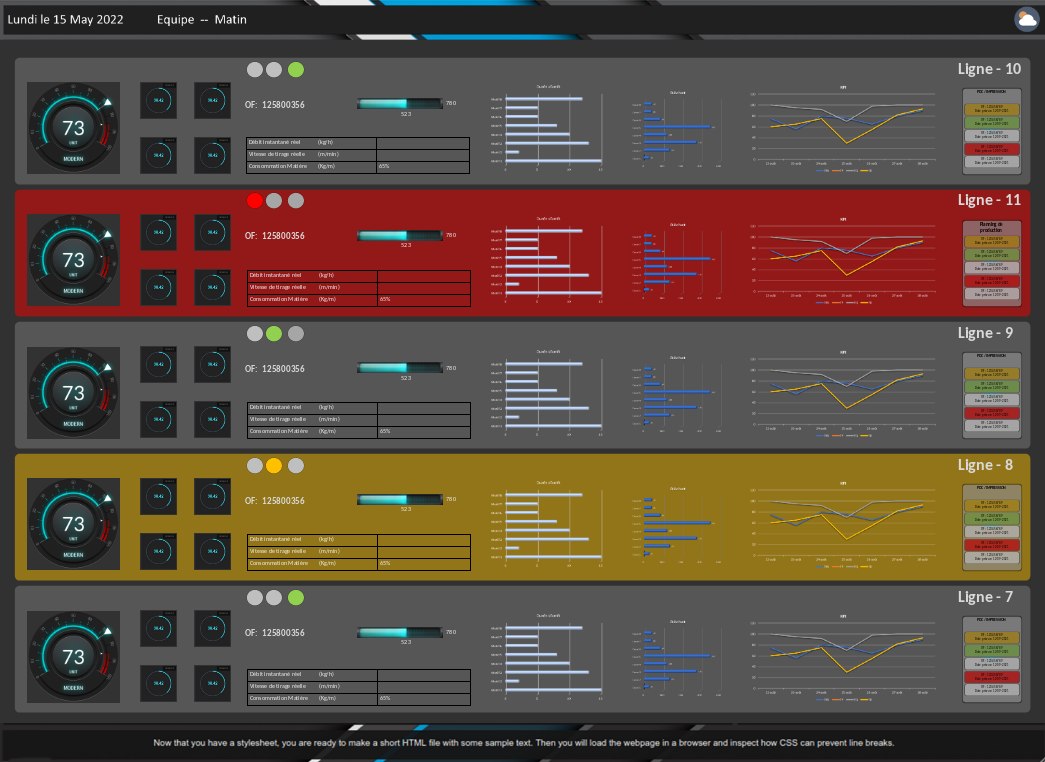

Andon Post

The Andon post interface within our Manufacturing Execution System (MES) serves as a critical communication tool, providing immediate visual updates on production status and issues. It displays real-time information on machine performance, production progress, and any alarms or stoppages, enabling rapid identification and resolution of problems. This interface promotes transparency and teamwork by ensuring that all team members are aware of the current state of production. With its clear and visible alerts, the Andon post enhances responsiveness and helps maintain smooth and efficient operations, ultimately contributing to improved productivity and reduced downtime.

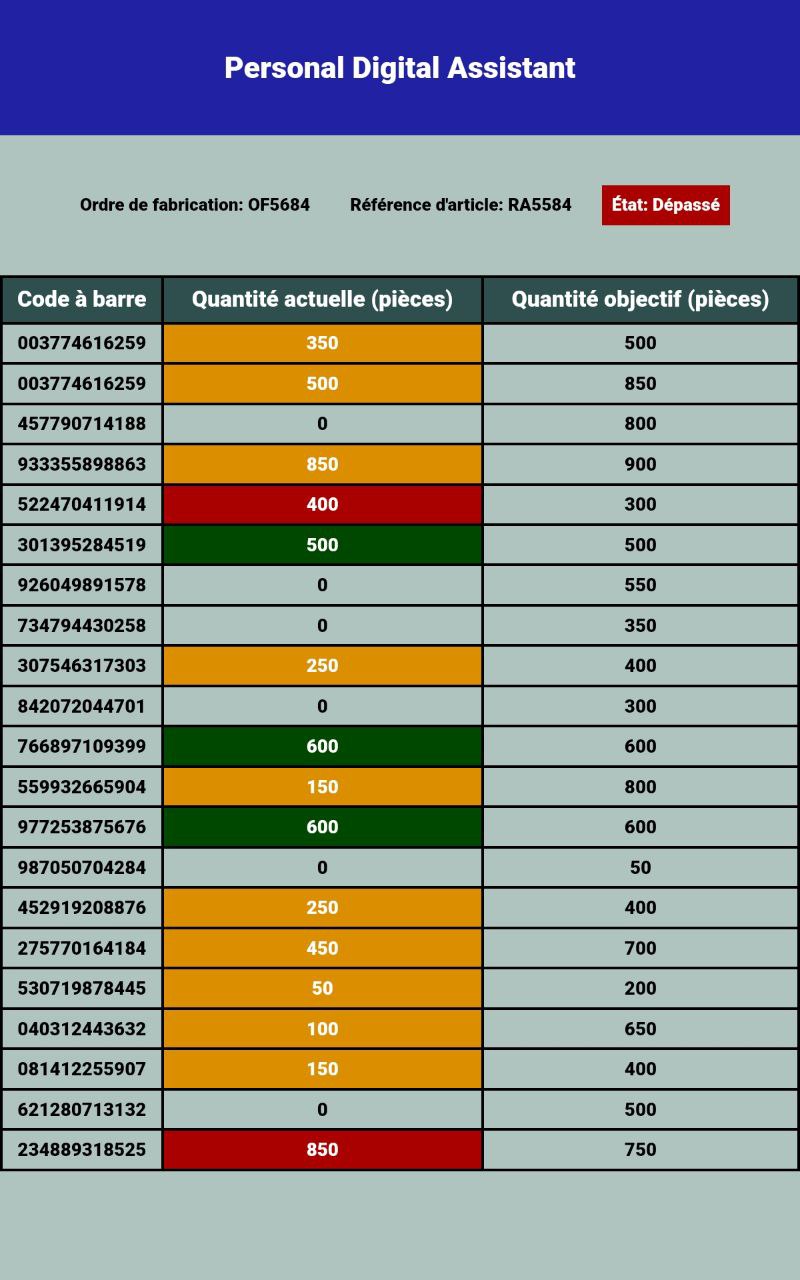

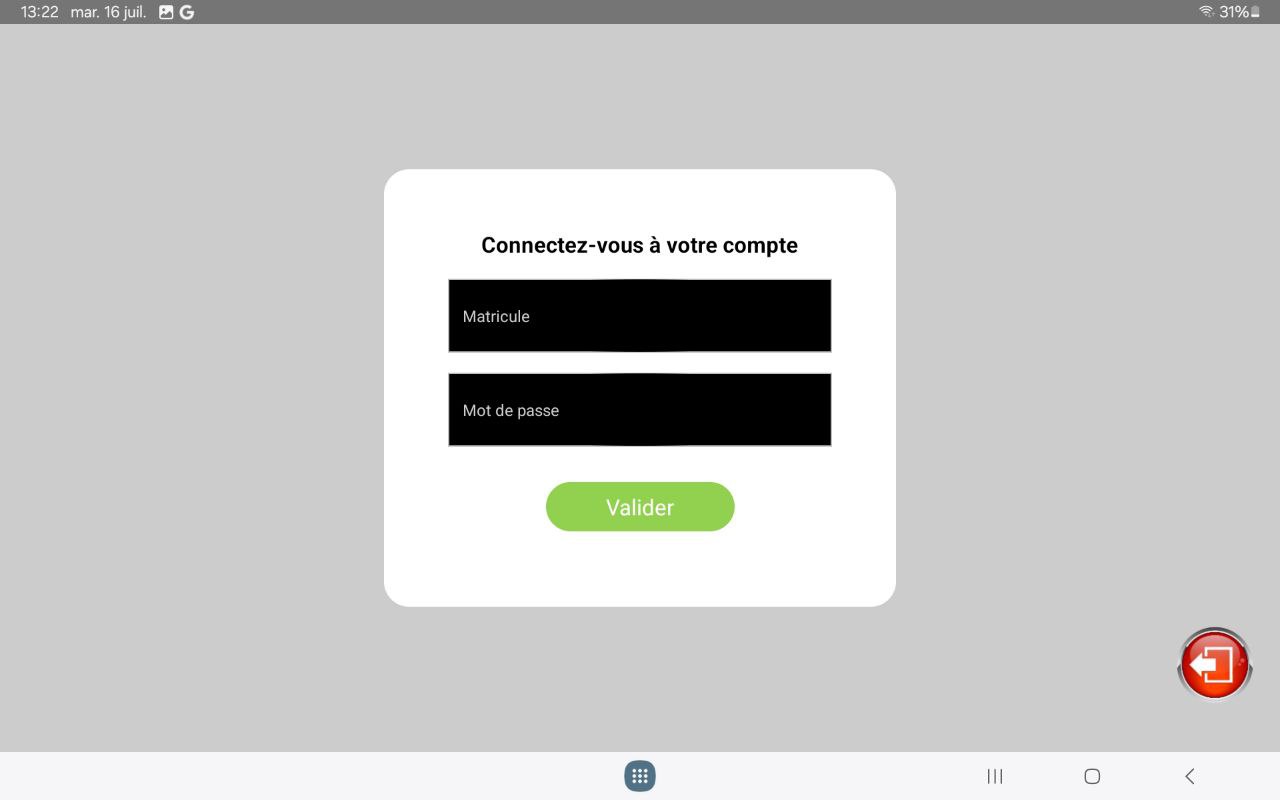

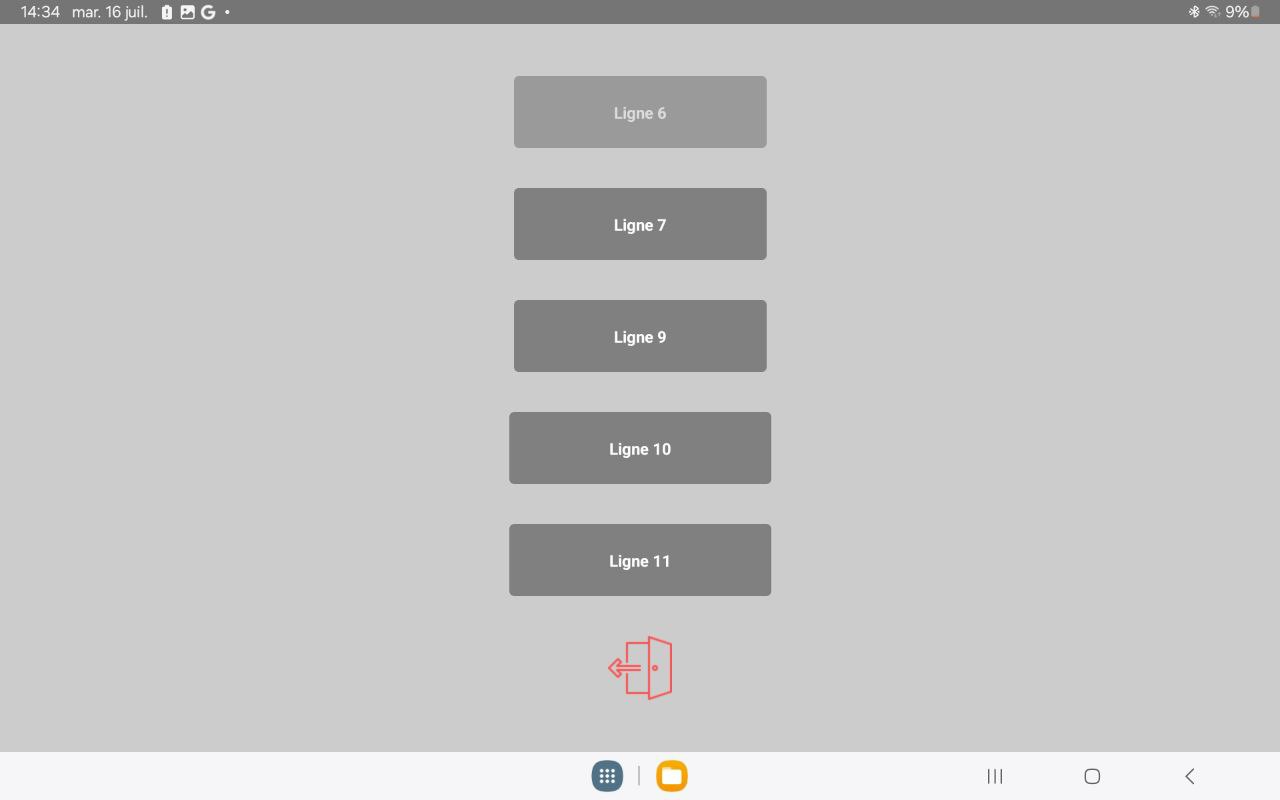

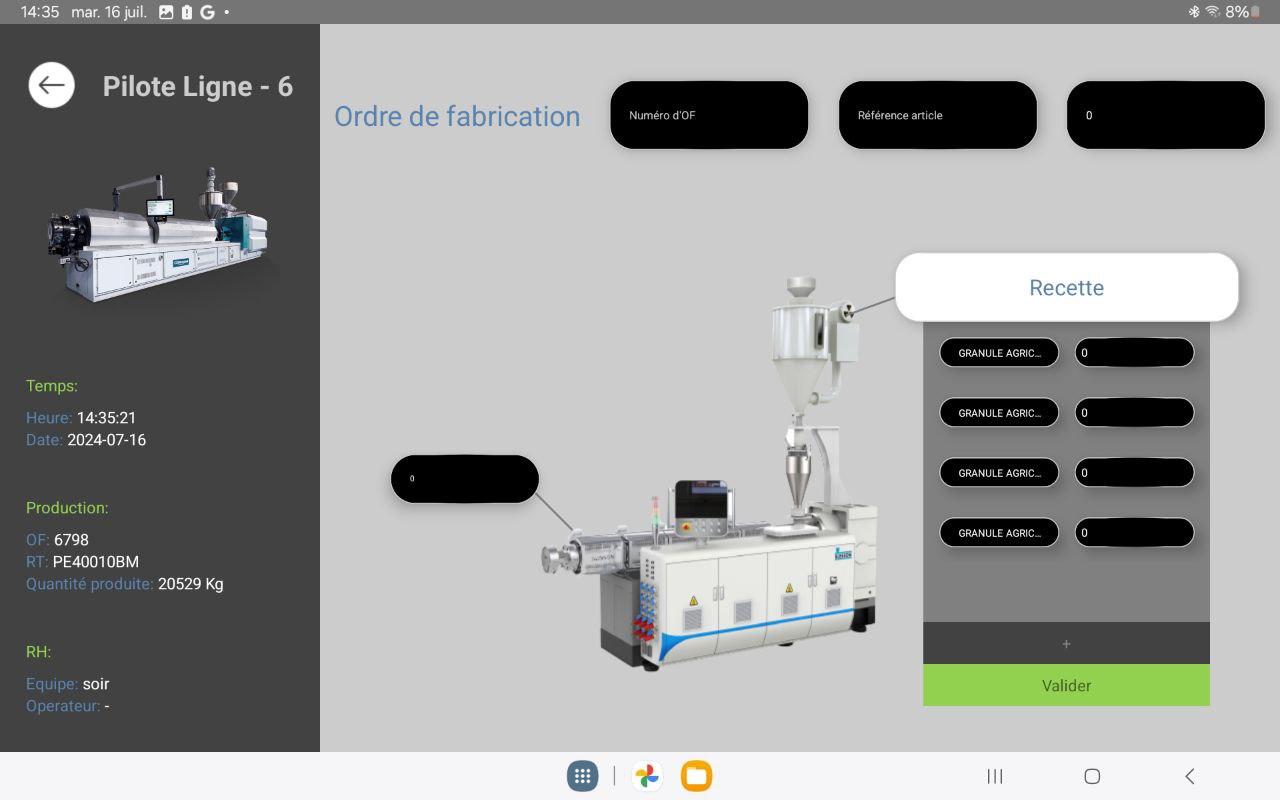

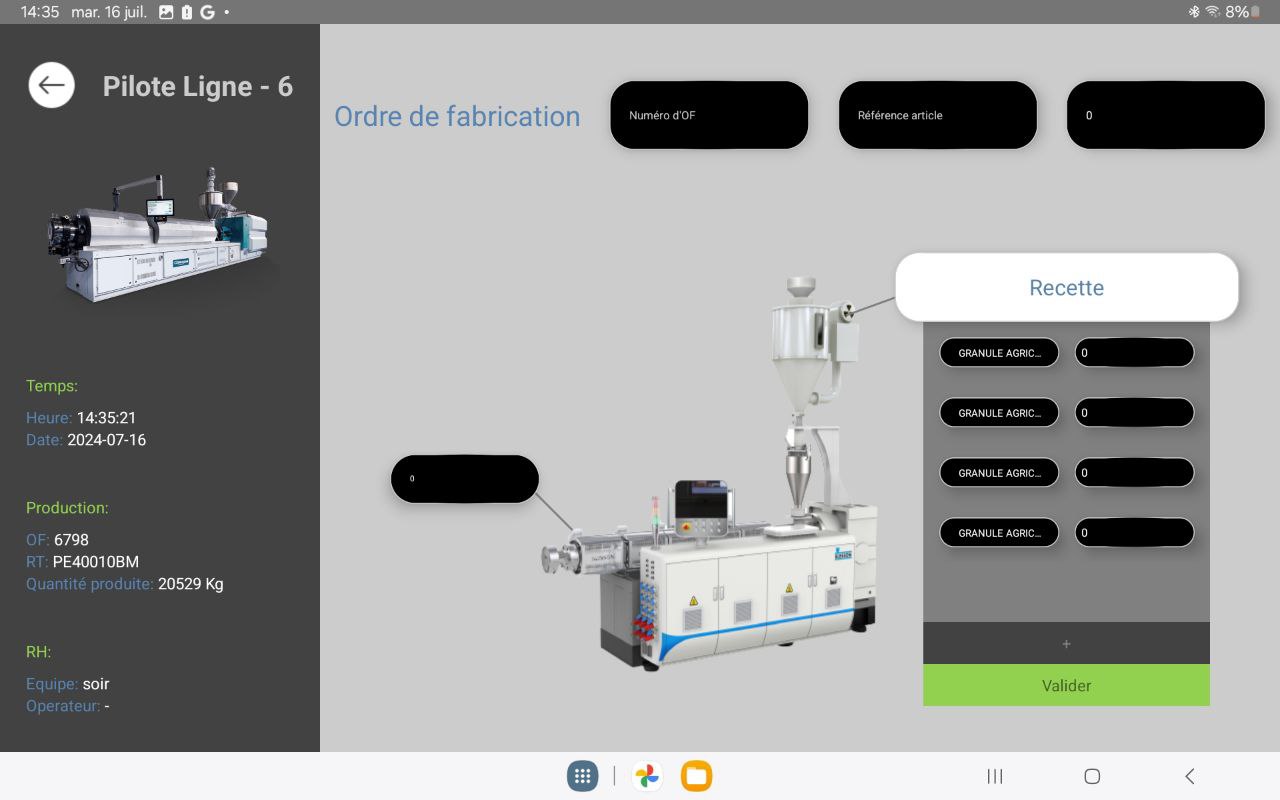

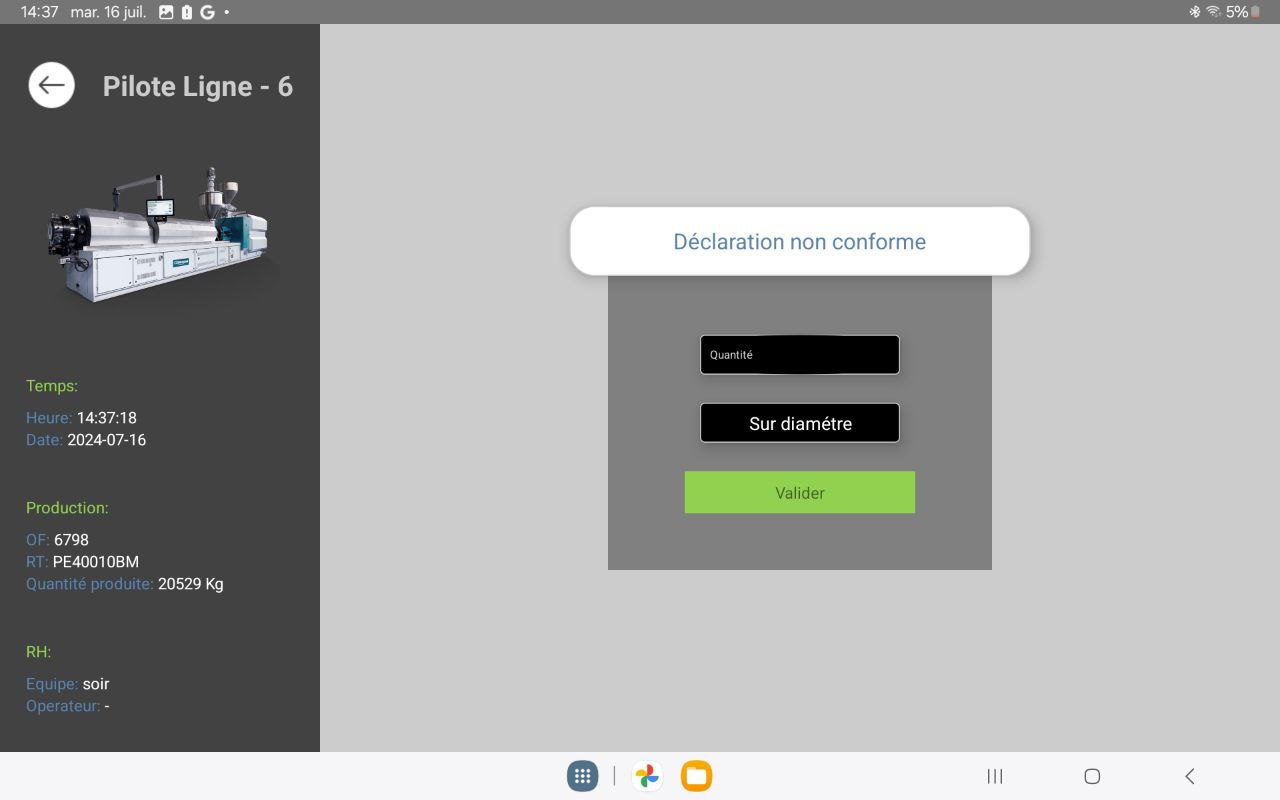

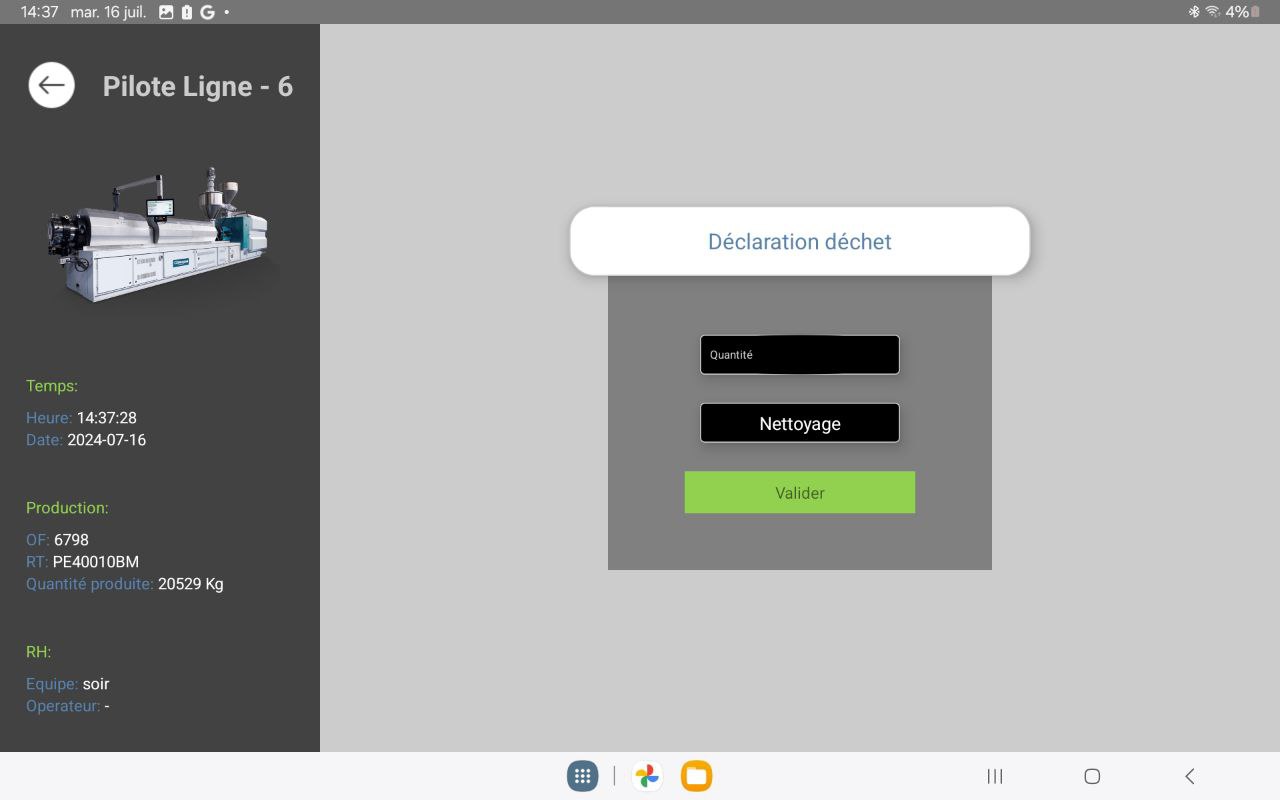

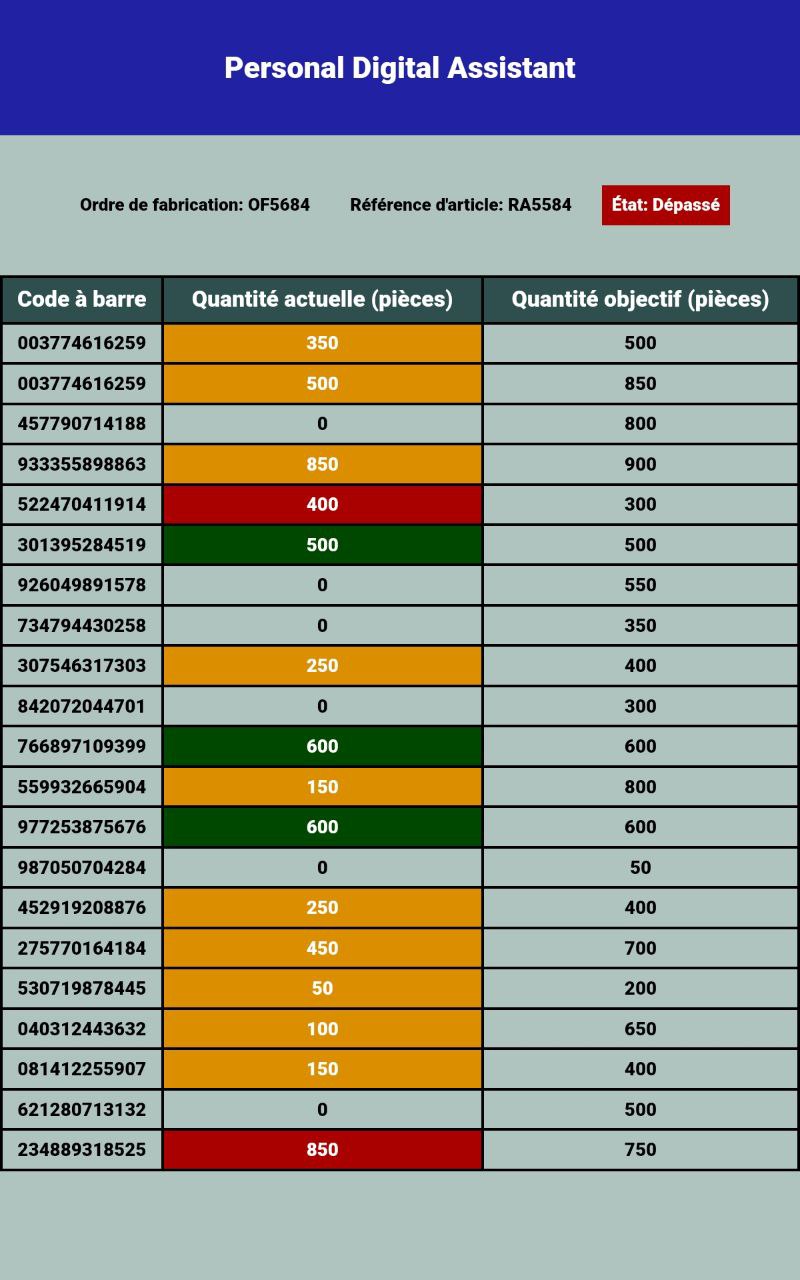

Personal Digital Assistant

The Personal Digital Assistant (PDA) plays a crucial role in our manufacturing operations by facilitating the efficient preparation of raw materials for fabrication orders. Integrated seamlessly with our production management system, the PDA enables operators to access detailed instructions and specifications directly on handheld devices. Operators can verify inventory levels, retrieve material specifications, and initiate material handling processes such as picking, packing, and staging. This mobile capability ensures that materials are prepared accurately and efficiently, reducing lead times and minimizing errors. By leveraging the PDA for material preparation, we enhance operational agility, streamline workflows, and maintain high standards of production efficiency and quality.

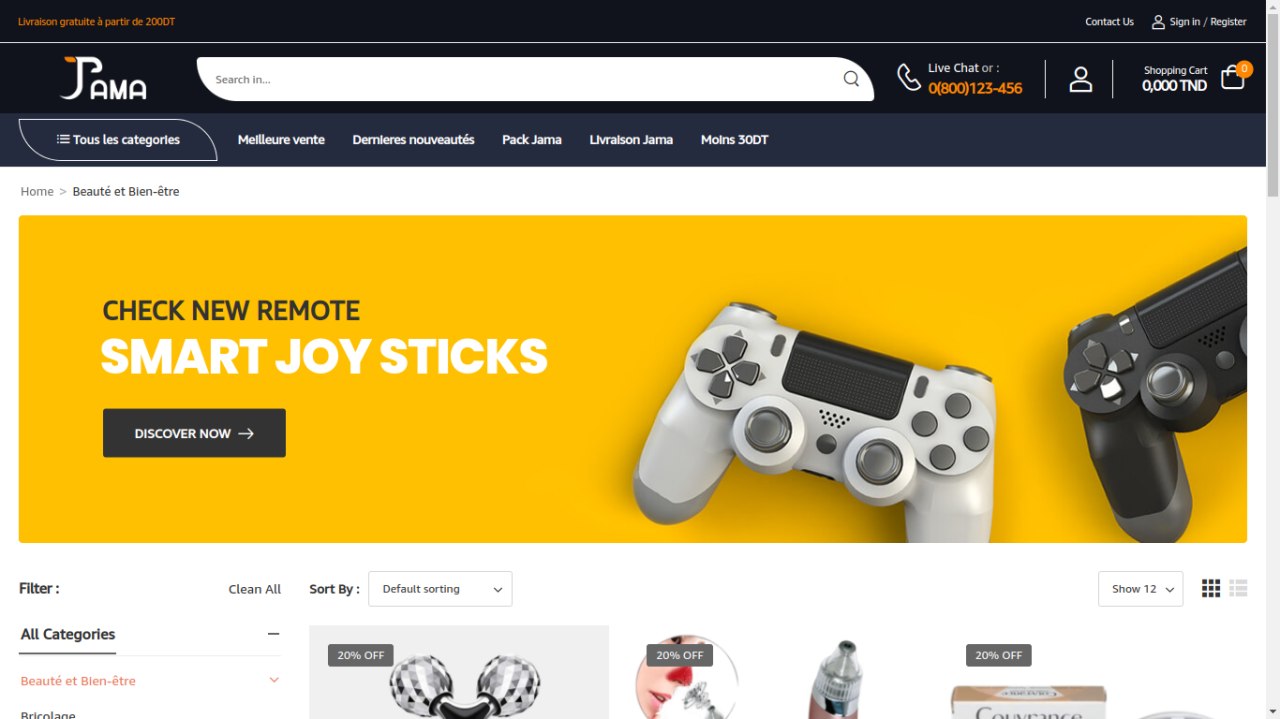

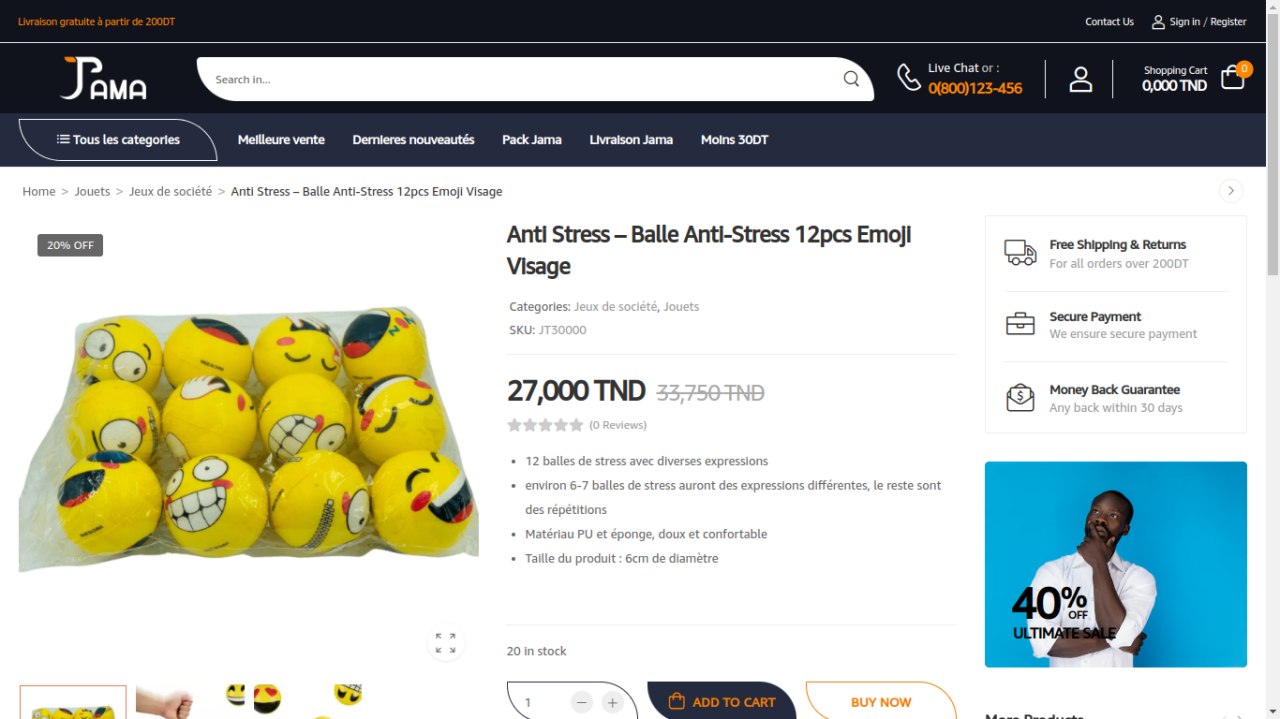

Jama E-Commerce Website

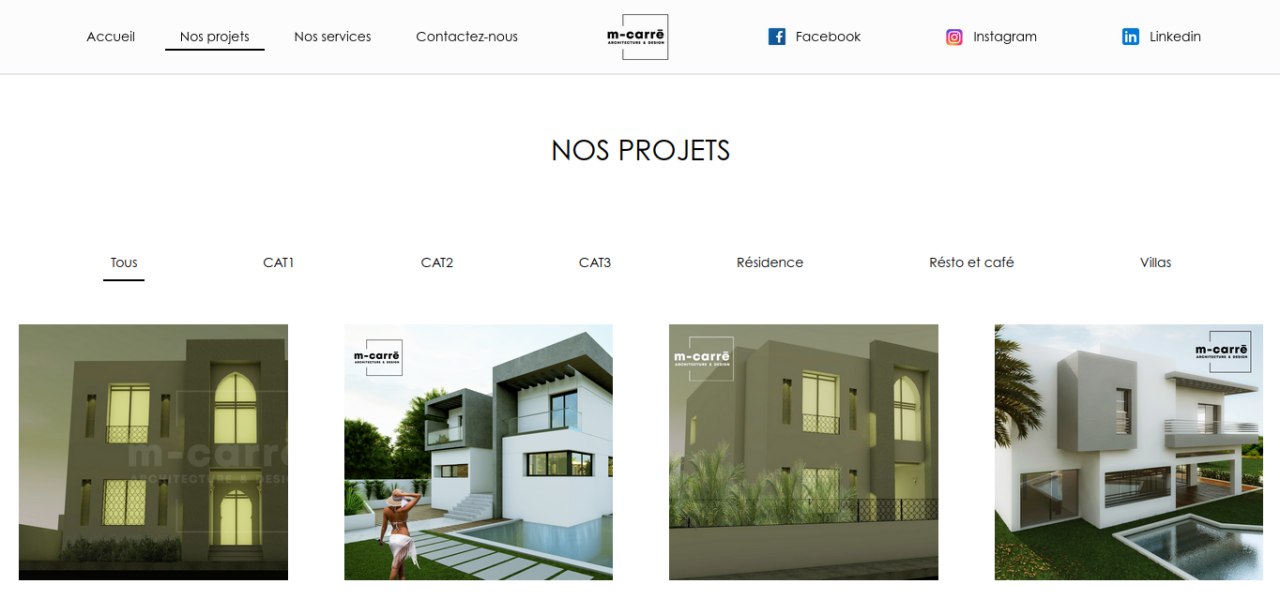

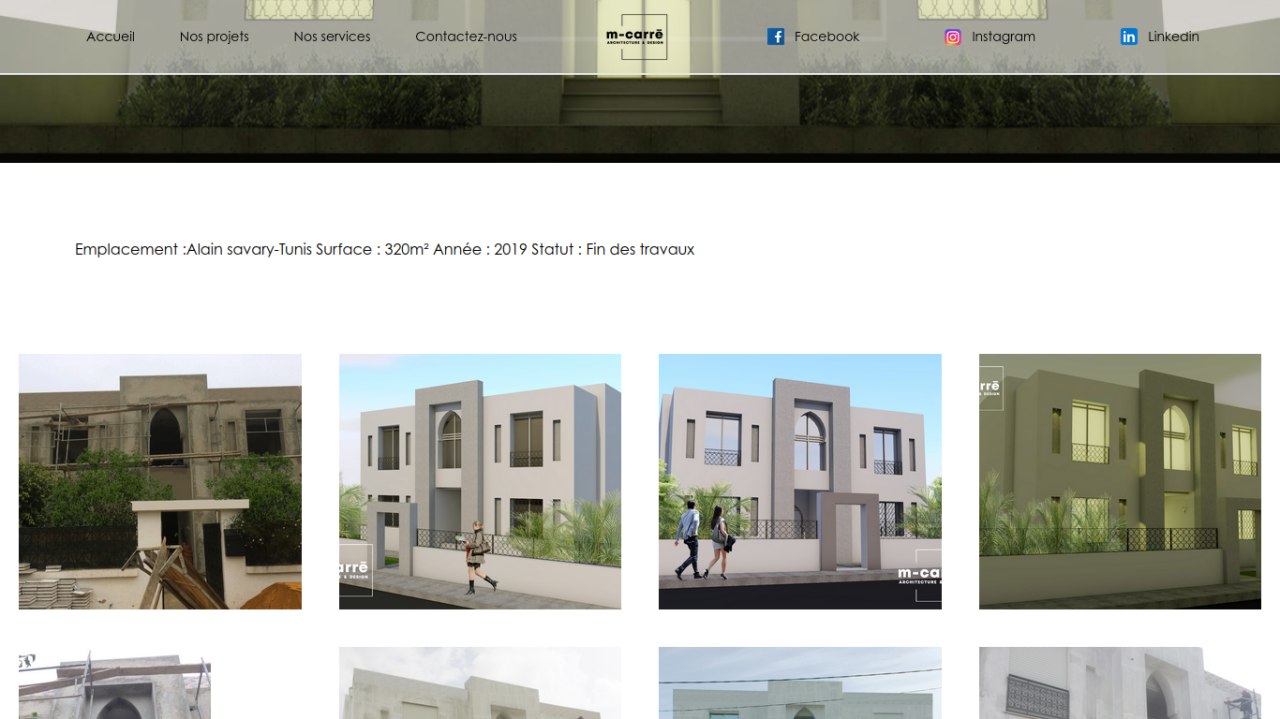

M-Carré Architecture Website

SDTM Website